Introduction

Organizations must have a clear understanding of how much work they can realistically support to deliver business priorities consistently. With multiple initiatives running in parallel, organizations must continuously assess available capacity to ensure delivery commitments can be met.

Without structured capacity planning, organizations face challenges, such as rising resourcing costs, sub-optimal utilization, and delivery delays. By transitioning away from reactive capacity planning approaches, firms ensure better resource allocation, reduced execution risk, and more predictable delivery outcomes.

This guide explores how effective capacity planning helps organizations align capacity with upcoming demand to improve delivery performance and boost business outcomes.

What is Capacity Planning? Definition & Core Concepts

Capacity planning is the strategic process of determining whether an organization has sufficient resources, such as people, equipment, budget, and technology, to meet current and future demand. It aligns available capacity with forecasted demand to prevent bottlenecks and ensure seamless operational workflow.

It involves a thorough comparison of the forecasted work with actual resource availability to identify potential capacity shortfalls or excesses. This analysis helps businesses make informed decisions on whether to scale their workforce or optimize the infrastructure to meet project goals and strategic growth targets.

In the following section, we will discuss how capacity planning benefits organizations.

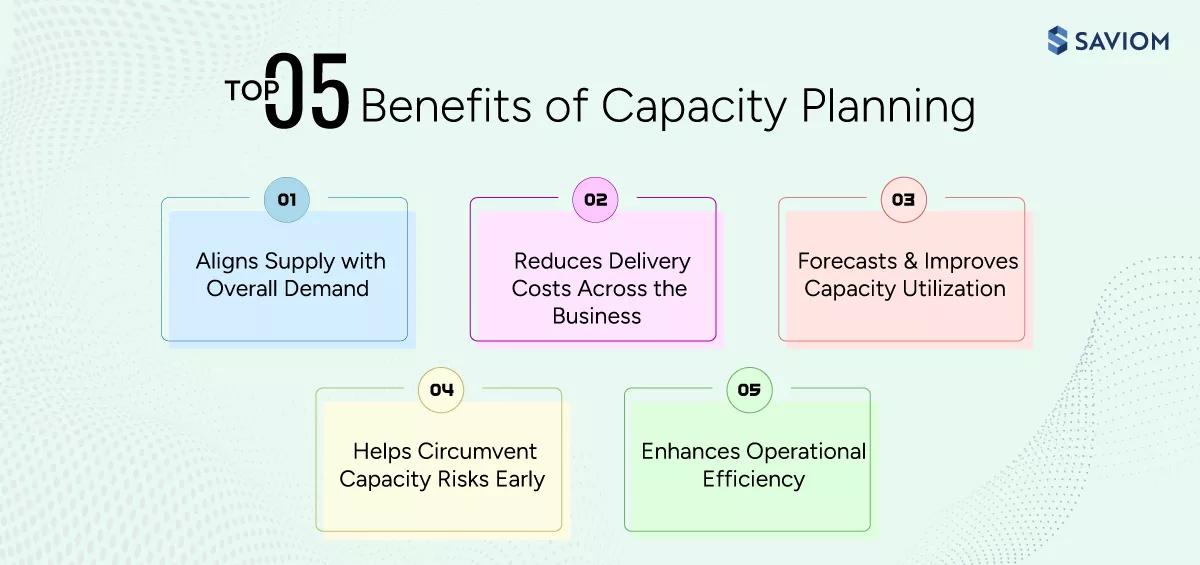

Why is Capacity Planning Important for Businesses?

Effective capacity planning directly impacts delivery predictability, cost efficiency, and organizational resilience. Without it, enterprises are forced into reactive decision-making, where options are limited and significantly more expensive.

Aligns Supply with Overall Demand

Capacity planning ensures the right mix of human and non-human assets is available to meet upcoming demand. By anticipating future demand, organizations can identify and secure the required capacity in advance. This prevents last-minute capacity shortages, prevents cost overruns, and ensures seamless execution of business initiatives.

Reduces Delivery Costs Across Business Initiatives

By seamlessly aligning capacity with total demand, including project work, operational, and strategic work, firms can avoid overstaffing, bench time, and emergency hiring. Organizations avoid paying for unused capacity and premium prices for reactive hiring, helping minimize overall delivery costs.

Discover cost reduction strategies to boost business profitability.

Forecasts and Improves Capacity Utilization

By forecasting utilization across billable, non-billable, and strategic work, firms can identify under- and overutilized capacity early. This enables them to take corrective actions and optimize the use of all resources, including workforce, assets, and equipment, reducing productivity loss and improving profitability.

Helps Circumvent Capacity Risks Early

Effective capacity management helps organizations assess whether in-house capacity can support future demand. This enables early identification of risks, such as capacity shortages, skill mismatches, and utilization imbalances, allowing corrective action to be taken in advance to mitigate delivery risks.

Read our blog on resource risks in project management.

Enhances Operational Efficiency

By ensuring the right resources, such as people, equipment, and technology, are available to support business initiatives, robust capacity planning enables work to start on time and progress smoothly. This reduces bottlenecks, improves workflow stability, and enhances overall operational efficiency.

Explore our comprehensive eBook on capacity planning to understand the best practices for effectively aligning capacity with demand.

Delivering these benefits requires organizations to understand and apply different types of capacity planning in project management based on resources, scope, and time horizon.

Types of Capacity Planning

Different capacity planning lenses help enterprises address constraints across resources, scope, and time horizons. Understanding these distinctions enables leaders to apply the right planning approach at the right decision level.

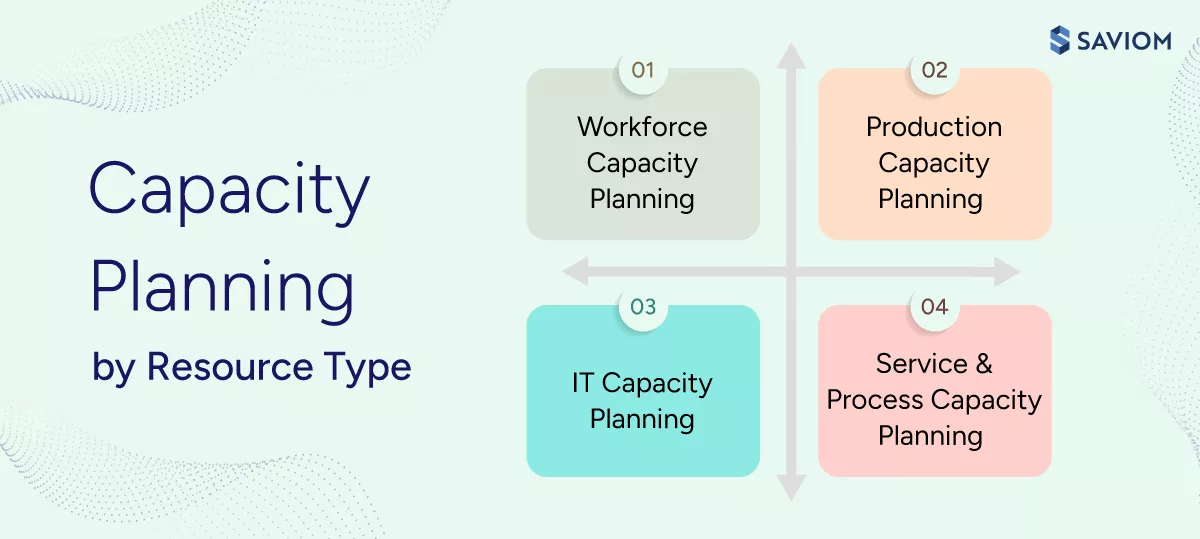

Capacity Planning by Resource Type

This lens focuses on ensuring sufficient capacity across resource categories, including workforce, assets, infrastructure, and operational systems. Take a look:

Workforce Capacity Planning

Workforce capacity planning is the process of forecasting workforce availability and capability against total work demand. It considers skills, experience levels, learning curves, attrition risk, and sustainable workload limits. It also accounts for non-billable but necessary activities, such as project meetings, training, and coordination to ensure realistic capacity planning.

Read our blog on workforce planning.

Production Capacity Planning

Production capacity planning is the process of aligning manufacturing output capability with forecasted demand. It focuses on equipment availability, facility constraints, work completion rate, and maintenance cycles to prevent production bottlenecks and asset underutilization.

IT Capacity Planning

IT capacity planning is the process of ensuring IT infrastructure, systems, and applications can support current and future demand reliably. It focuses on balancing performance, scalability, cost, and operational risk across technology platforms. It is especially important during digital transformation, cloud migration, and periods of rapid user growth.

Service & Process Capacity Planning

Service and process capacity planning is the process of optimizing operational workflows, both customer-facing and internal, to meet service demand effectively. It considers response times, service levels, approval cycles, process delays, etc. Even with sufficient capacity, inefficient processes can reduce delivery speed and service quality.

Capacity Planning by Scope

This lens focuses on how capacity is planned and managed across different organizational levels, from enterprise-wide strategy to team-level execution. Let’s examine.

Enterprise-Level Capacity Planning

Enterprise-level capacity planning is the process of managing capacity across the organization to support strategic priorities and investment decisions. It provides end-to-end visibility and enables managers to make data-driven trade-offs across competing demand, growth priorities, and operational risk.

Team-Level Capacity Planning

Team-level capacity management is the process of aligning team capacity with near-term work demand. It balances execution work with support activities and unplanned interruptions. While focused on operational execution, it remains aligned with enterprise priorities to prevent resource constraints across the organization.

Capacity Planning by Time Horizon

This lens focuses on planning capacity across short-, medium-, and long-term planning windows.

Operational Capacity Planning

Operational capacity planning is the process of managing short-term demand using available capacity. It focuses on scheduling, intake management, handling unplanned interruptions, etc., across daily or weekly work. The goal is to maintain workflow stability, prevent delivery delays, and ensure consistent service performance.

Deep dive into operational workforce planning and its importance.

Tactical Capacity Planning

Tactical capacity planning is the process of managing medium-term demand using planned capacity adjustments. It focuses on hiring plans, outsourcing decisions, technology enhancements, etc., over a 6–24 month horizon. The goal is to prevent emerging capacity gaps and support consistent delivery performance.

Strategic Capacity Planning

Strategic capacity planning is the process of future capacity requirement planning based on business growth and market strategy. It focuses on workforce scale, technology platforms, and capital investments over a multi-year horizon. The goal is to ensure firms can sustain future demand and support long-term business expansion.

Now let’s take a look at the key steps involved in effective capacity planning.

Step-by-Step Capacity Planning Framework for Enterprises

This framework provides a repeatable approach that connects demand forecasting to practical capacity decisions across the enterprise.

Step 1: Accurately Forecast Business Demand

Identify all sources of demand across projects, operations, support, compliance, and change initiatives. Define forecast ranges, demand certainty ranges, and volatility assumptions instead of relying on single-point estimates. Also, maintain continuously updated forecasts to ensure demand signals reflect evolving business objectives.

Step 2: Build a Centralized Resource Inventory

Establish a unified view of effective capacity across human and non-human resources. For people, capture skills, competencies, and proficiency levels; for non-human resources, such as technology, equipment, and assets, assess capacity in terms of functional capability, performance limits, output potential, and availability.

Understand what a skill matrix is and why it is important for businesses.

Step 3: Analyze Capacity vs. Demand Gaps

Compare available capacity against forecasted demand to identify excess or shortages. Next, quantify gaps by resource type, skill level, and system capability to expose true constraints. Additionally, validate findings against actual delivery performance, not just headcount or budget metrics.

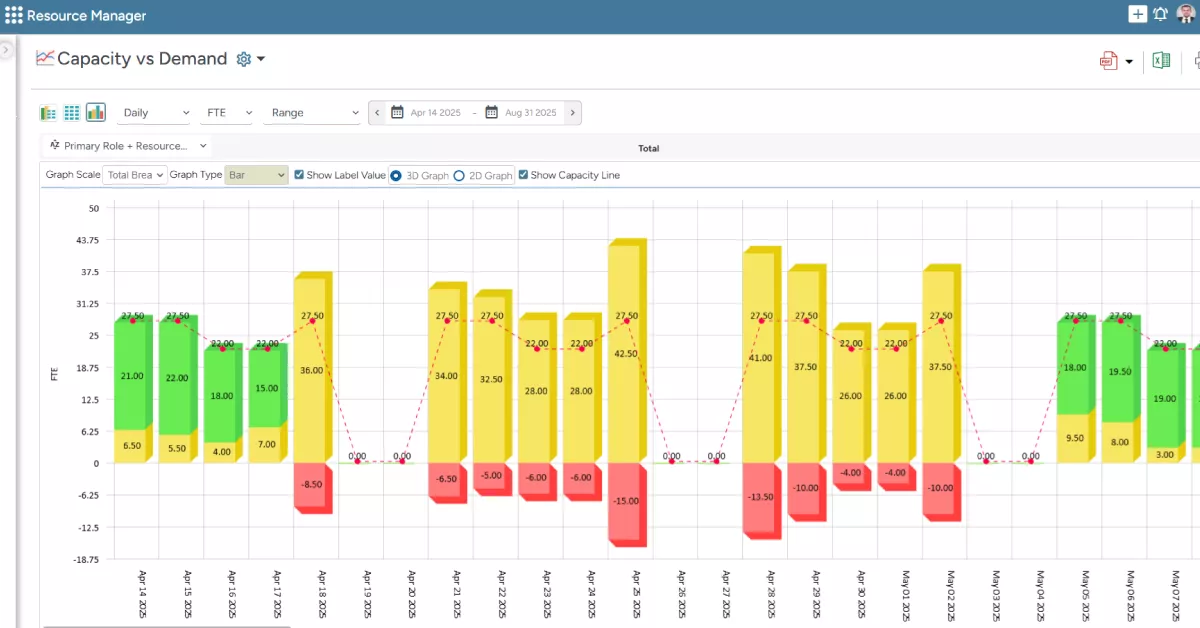

SAVIOM’s Capacity vs. Demand Graph enables managers to spot resource shortages and excesses, and take timely action to balance supply and demand.

SAVIOM’s Capacity vs. Demand Graph enables managers to spot resource shortages and excesses, and take timely action to balance supply and demand.

Step 4: Perform Scenario Modeling

Evaluate best-case, worst-case, and most-likely demand and capacity scenarios. Assess the potential impact of attrition, outages, funding delays, and demand interruptions before they affect delivery and business continuity across planned initiatives and operational workloads.

Read our blog on scenario planning.

Step 5: Optimize Capacity Effectively

Adjust capacity using hiring, redeployment, automation, asset upgrades, or process redesign. Prioritize demand where required by resequencing work, reallocating tasks, or deferring lower-value activities. Lastly, continuously monitor outcomes and refine capacity decisions based on real performance signals.

Explicit trade-offs between cost, risk, speed, and sustainability ensure decisions align with strategic priorities. Let us understand various capacity planning strategies.

What are the Different Capacity Planning Strategies?

Capacity planning strategies describe when organizations choose to add or release capacity relative to demand. Most enterprises use a blend rather than a standalone strategy.

Lead Strategy

A lead strategy adds capacity ahead of expected demand across the workforce, systems, or assets. It prioritizes service readiness, delivery continuity, and growth enablement. This strategy is commonly used where service delays are costly or demand is highly predictable.

Lag Strategy

A lag strategy adds capacity only after demand is confirmed. It focuses on cost efficiency and optimal resource utilization. However, it increases the risk of capacity shortages, delivery delays, and reactive resourcing during demand spikes, and service performance degradation.

Match Strategy

A match strategy adjusts capacity incrementally as demand changes, balancing resource efficiency with responsiveness to demand fluctuations. It requires strong demand visibility and flexible capacity adjustment mechanisms. This approach works best in environments with moderate volatility and disciplined resource planning processes.

After strategies, let us move on to capacity planning metrics.

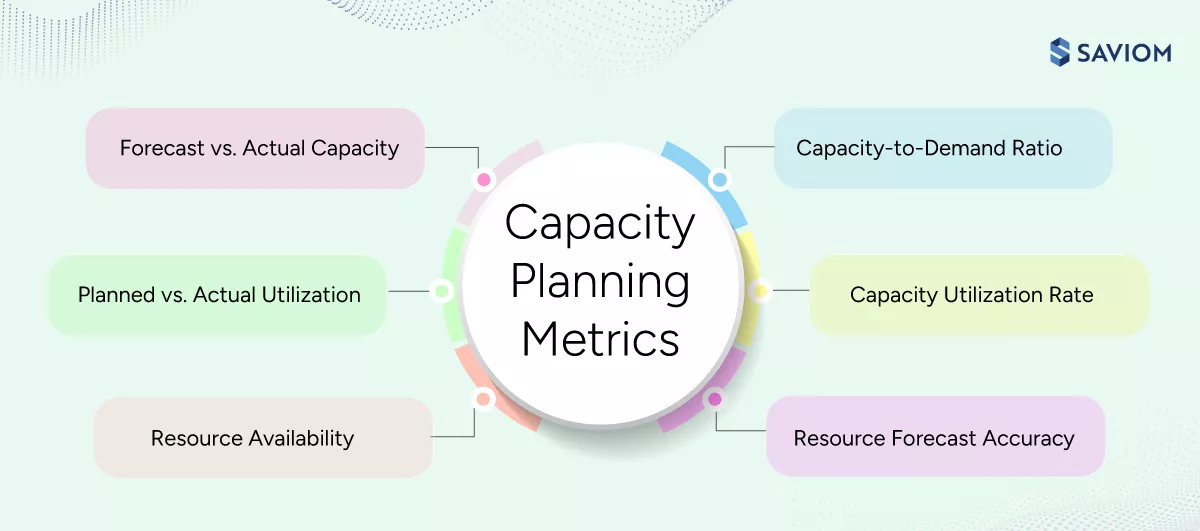

Capacity Planning Metrics & KPIs to Measure Success

Capacity planning KPIs are not performance scorecards; they are early warning signals that reveal whether demand and capacity are drifting out of balance before delivery failure occurs.

Capacity-to-Demand Ratio

The capacity-to-demand ratio measures whether total effective capacity is sufficient to meet forecasted project demand within a given timeframe. It highlights capacity surplus or shortages early, enabling informed resourcing decisions on time.

The formula to calculate the capacity-to-demand ratio is:

Capacity Utilization Rate

The capacity utilization rate measures the percentage of usable capacity currently consumed by work. If the utilization levels are constantly high, it indicates rising delivery risk, reduced resilience, and increased burnout rather than operational excellence.

The formula to calculate the capacity utilization rate is:

Resource Forecast Accuracy

Resource forecasting accuracy measures how closely forecasted capacity usage matches actual capacity consumption over time. Low accuracy indicates resource planning bias or unreliable demand assumptions, reducing the effectiveness of resource capacity planning decisions.

The formula to calculate resource forecasting accuracy is:

Read our blog on resource capacity forecasting.

Resource Availability

Resource availability rate measures the percentage of capacity available for new or upcoming work. Low availability indicates limited flexibility to absorb demand spikes or support new initiatives.

The formula to calculate the resource availability rate is:

Planned vs. Actual Utilization

Planned vs. actual utilization compares expected workload against actual capacity usage to identify delivery gaps, project scope changes, or operational inefficiencies. Persistent deviations indicate that planning assumptions do not reflect actual execution conditions.

The formula to calculate planned vs. actual utilization is:

Forecast vs. Actual Capacity Variance

Capacity variance measures the difference between forecasted and actual delivered capacity over time. Persistent variance often signals inaccurate assumptions about business productivity, operational interruptions, or work completion rate.

The formula to calculate capacity variance is:

Understand how to measure resource capacity and demand.

Now, let us understand the difference between capacity planning, resource planning, and demand planning.

Capacity Planning vs. Resource Planning vs. Demand Planning

Understanding the distinction between these critical planning disciplines is essential, as organizations often attempt to solve capacity challenges using the wrong planning approach.

| Aspect | Capacity Planning | Resource Planning | Demand Planning |

|---|---|---|---|

| Primary Focus | Ensuring total capacity sufficiency | Allocating resources to work | Managing demand volume and trends |

| Core Question | Do we have enough capacity? | Who should work on what? | How much demand is expected? |

| Time Horizon | Short- to long-term | Tactical and operational | Short- to long-term |

| Ownership | Executive leadership and portfolio teams | Delivery leaders and resource managers | Sales, finance, and operations teams |

| Output | Capacity targets and thresholds | Resource allocation plans | Demand forecasting and projections |

| Risk Addressed | Under- or overcapacity risk | Resource overallocation or conflicts | Forecast inaccuracies and demand volatility |

Let us look at the various capacity planning challenges organizations face and their solutions.

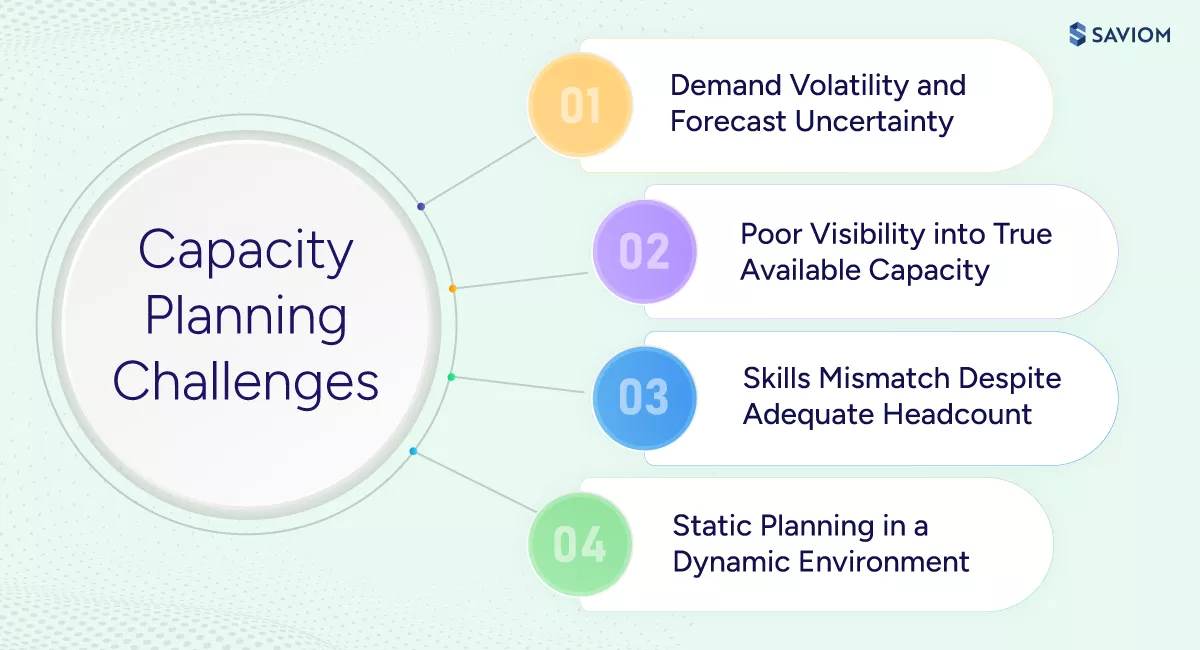

Capacity Planning Challenges & How Enterprises Overcome Them

Capacity planning challenges can delay project initiation and reduce overall business profitability. Below are the most common challenges that organizations face:

Demand Volatility and Forecast Uncertainty

Challenge:

Enterprise demand rarely follows stable or predictable patterns. Regulatory changes, seasonal spikes, and sudden project leadership reprioritization can invalidate demand assumptions quickly. Moreover, overreliance on optimistic demand projections often leads to either a capacity shortage or an excess.

How to address it:

Plan using demand ranges instead of single-point numbers to absorb uncertainty. Additionally, revisit demand assumptions quarterly and tie them directly to execution data.

Poor Visibility into True Available Capacity

Challenge:

Most organizations overestimate capacity by ignoring leaves, PTO, training, internal initiatives, support work, and context-switching. Though capacity appears sufficient on paper, it collapses during execution when unplanned work absorbs time. This creates a false sense of readiness and late-stage delivery risk.

How to address it:

Managers should model effective capacity instead of theoretical capacity. Additionally, they should explicitly account for non-project and contingency work while planning capacity.

Read our blog on resource availability.

Skills Mismatch Despite Adequate Headcount

Challenge:

Having enough people does not mean having the right capabilities. Specialist skills, certifications, or domain experience often become hidden bottlenecks, delaying delivery even when overall utilization appears healthy. Most often, generic capacity metrics fail to capture this nuance.

How to address it:

Organizations should shift from role-based to skills-based capacity planning. For this, they can track critical skills availability alongside headcount metrics.

Overcome capacity planning challenges with SAVIOM’s advanced software to ensure timely resource availability, enhance delivery predictability, and support better capacity decisions. Book a Demo Today.

Static Planning in a Dynamic Operating Environment

Challenge:

Annual or semi-annual capacity plans quickly become outdated in fast-changing business environments. Organizations treat capacity plans as paperwork rather than decision-support systems, leading to reactive firefighting when assumptions prove to be inaccurate.

How to address it:

Businesses must adopt continuous capacity planning cycles supported by scenario planning. This enables proactive decision-making, faster course correction, and more predictable delivery outcomes.

Deep dive into resource planning.

After challenges, it is time to learn capacity planning best practices.

Enterprise Capacity Planning Best Practices

Here’s a rundown of the capacity planning best practices that businesses must follow to gain a competitive edge:

Align Capacity Planning with Strategic Priorities

Capacity planning should explicitly reflect the overall enterprise strategy. When capacity constraints arise, leaders must be able to see which initiatives are strategically critical and which can be delayed or deprioritized. This proactive approach prevents silent trade-offs that undermine long-term objectives.

Plan for Sustainable Utilization, Not Maximum Output

Organizations that consistently operate at peak utilization leave little buffer for disruption, increasing the chances of delivery delays. Mature organizations should plan for sustainable utilization ranges to improve work completion rate, reduce burnout, and enhance employee productivity over time.

Learn how to optimize resource utilization.

Incorporate Scenario Planning into Decision-Making

Scenario planning allows organizations to create multiple capacity scenarios and evaluate factors, such as demand shifts, cost fluctuations, unplanned attrition, etc. By testing these variables across different scenarios, leaders can compare trade-offs and select the most viable capacity plan based on risk, cost, and delivery commitments.

Continuously Improve Forecast Accuracy

Capacity planning is an ongoing discipline that improves with continuous feedback from execution. Organizations should regularly compare planned demand and capacity against actual outcomes to identify bias in assumptions, hidden workload patterns, and systemic inefficiencies.

Read our blog on resource forecasting.

Now that the best practices are clear, let us look at some practical capacity planning examples.

Real-World Capacity Planning Examples

Below are some industry-specific capacity planning examples:

Technology and Product Engineering

A global fintech company expanding its product portfolio experienced repeated release delays despite aggressive hiring. Capacity analysis revealed that the senior engineer review and architecture validation bandwidth was the primary bottleneck.

By redistributing review workloads, introducing review buffers, and adjusting release schedules, the organization improved release predictability without increasing headcount.

Professional Services and Consulting

A multinational consulting firm faced recurring overutilization during peak sales cycles due to sudden deal closures. By modeling multiple pipeline scenarios, managers identified when external capacity would be required in advance.

This significantly reduced workload pressure on teams, increased employee productivity, and supported consistent revenue performance.

Explore the benefits of capacity planning in a professional services firm.

Construction and Infrastructure

An engineering and construction contractor delivering multi-year infrastructure projects faced recurring schedule risks due to a shortage of certified safety and compliance engineers. In this scenario, skills-based capacity building highlighted the risk early, enabling targeted hiring and onboarding of specialist subcontractors.

Capacity planning across project phases helped managers spot the constraint early and initiate targeted hiring and specialist subcontractor onboarding ahead of regulatory inspection milestones.

Audit, Accounting, and Legal Services

A global audit firm applied capacity planning to manage seasonal compliance-driven workloads better. By explicitly accounting for partner review time and critical support functions, the firm improved workload distribution across teams.

This led to higher audit quality, reduced last-minute overtime during peak filing periods, and improved delivery predictability during regulatory deadlines.

Learn about the capacity planning challenges in audit & accounting firms.

After looking at the real-world examples, let us move on to the future trends of capacity planning.

Future of Capacity Planning

The future of capacity planning is driven by better sensing, faster adjustment, and smarter decision support, not by eliminating human judgment.

AI-Enhanced Demand Sensing

AI models increasingly analyze historical delivery data, pipeline signals, and operational patterns to detect early shifts in demand. These insights reduce manual forecasting effort and highlight risks earlier, while still requiring human oversight for pattern detection, risk assessment, and decision validation.

Predictive and Prescriptive Capacity Analytics

Predictive analytics identify where capacity shortfalls are likely to occur, while prescriptive analytics recommend corrective actions, such as retraining/upskilling, hiring, reprioritization, or outsourcing. High-performing organizations use these tools to accurately evaluate trade-offs before committing resources.

Digital Twins for Capacity Simulation

Digital twins allow enterprises to simulate how the workforce, systems, and assets behave under different demand planning scenarios. This enables managers to test capacity decisions in a virtual environment before implementing them in live operations and reduces the unnecessary cost and risk of real-world experimentation.

Shift Toward Skills-Centric and Augmented Capacity

Future capacity models focus on skills rather than roles and incorporate automation and AI as capacity multipliers. This proactive approach increases flexibility while acknowledging that human expertise remains a finite and valuable constraint in effective capacity planning.

Now, let us understand what considerations need to be made while selecting the best capacity planning tool.

How to Select the Best Capacity Planning Software

The right capacity planner enables leaders to see constraints early, test decisions safely, and align capacity with business needs. Selecting capacity planning software is, therefore, a strategic decision.

Alignment with Business Needs

The most critical selection criterion is whether the tool supports strategic, tactical, and operational planning simultaneously. Enterprise capacity planning spans workforce, shared services, systems, facilities, and external vendors. Therefore, the platform must also match the scale and complexity of your organization.

Integration Capabilities

Capacity planning accuracy depends on seamless integration with third-party enterprise systems such as ERP, HR, project management, and financial platforms. Strong integration ensures capacity plans reflect real-time changes and allows leaders to respond to emerging constraints before they impact delivery.

Features and Capabilities

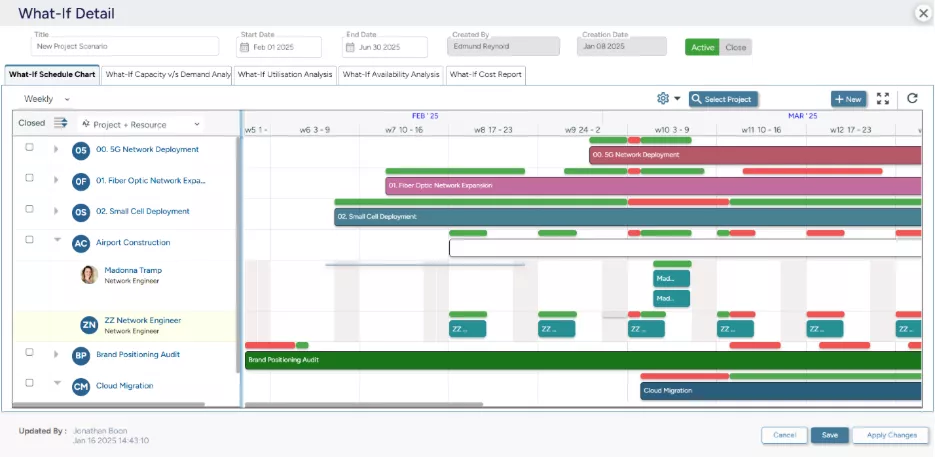

A modern capacity planning solution should offer multi-dimensional forecasting capabilities, a competency matrix, advanced what-if scenario modeling, etc. Together, these capabilities enable organizations to forecast, simulate, and optimize capacity planning decisions within a single connected platform.

SAVIOM’s Scenario Modeling empowers managers to compare multiple capacity plans and select the most viable option based on demand, skills, and available resources.

SAVIOM’s Scenario Modeling empowers managers to compare multiple capacity plans and select the most viable option based on demand, skills, and available resources.

Scalability, Usability, and Collaboration

A capacity planning tool must scale as the organization grows, supporting new business units and regions, and handling increasing planning complexity. Intuitive interfaces and role-based access are essential for enterprise-wide adoption.

The platform should also enable teams to collaborate easily on demand and capacity decisions. This helps reduce silos and improve alignment across business units.

Cost of Ownership and Vendor Support

Organizations should evaluate the total cost of ownership beyond licensing costs, including implementation effort, integrations, user adoption, training, and vendor support quality. Understanding these factors helps avoid hidden costs and ensures long-term sustainability.

Conclusion

Capacity planning is not an operational afterthought; it is a leadership discipline that determines whether organizations scale sustainably or operate in perpetual recovery mode. By aligning demand with real, effective capacity, enterprises improve predictability, protect their workforce, and make smarter investment decisions.

Frequently Asked Questions (FAQs)

Capacity planning is the process of aligning available organizational resources with forecasted demand to ensure reliable delivery across all business initiatives. It helps organizations anticipate resource constraints, ensure the availability of the right skills, and make informed investment decisions before execution risk materializes.

The top benefits of capacity planning are:

1. Aligns Supply with Overall Demand

2. Reduces Delivery Costs Across the Business

3. Forecasts & Improves Capacity Utilization

4. Helps Circumvent Capacity Risks Early

5. Enhances Operational Efficiency

The primary strategies are lead, lag, and match. Organizations often blend these approaches based on demand volatility, service criticality, and risk tolerance—investing early where reliability matters and reacting where flexibility is acceptable.

The best practices for effective capacity planning include:

1. Align Capacity Planning with Strategic Priorities

2. Plan for Sustainable Utilization

3. Incorporate Scenario Planning into Decision-Making

4. Continuously Improve Forecast Accuracy

The most common capacity planning challenges are:

1. Align Capacity Planning with Strategic Priorities

2. Plan for Sustainable Utilization

3. Incorporate Scenario Planning into Decision-Making

4. Continuously Improve Forecast Accuracy